Jhenten Bag Filter Stainless Steel 304 316L Water Treatment Winery Brewery

Description

Basic Info.

| Warranty | 1 Year |

| Material | SS304, SS316 |

| Manufacturing Process | Be Equipped with Jacket and Insulation Layer |

| Core Components | Pressure Vessel |

| Warranty of Core Components | 1 Year |

| Showroom Location | None |

| Connection | Flange/ Tc/ Thread |

| Local Service Location | None |

| Surface Treatment | Electrical Polish, Mirror Polish, Sand Polish, Aicd |

| Application | Water Treatment Winery Brewery |

| Key Selling Points | Key Selling Points: |

| Marketing Type | Hot Product |

| After Warranty Service | Online Support |

| Video Outgoing-Inspection | Not Available, Provided |

| Machinery Test Report | Not Available |

| Quick Details Place of Origin | 1 Year |

| Transport Package | Pump |

| Specification | #1 #2 #3 #4 bag |

| Trademark | JhenTen |

| Origin | China |

| Production Capacity | 50 Piece/Pieces Per Month |

Product Description

bag filter stainless steel 304 316L water treatment winery brewery

Product Description

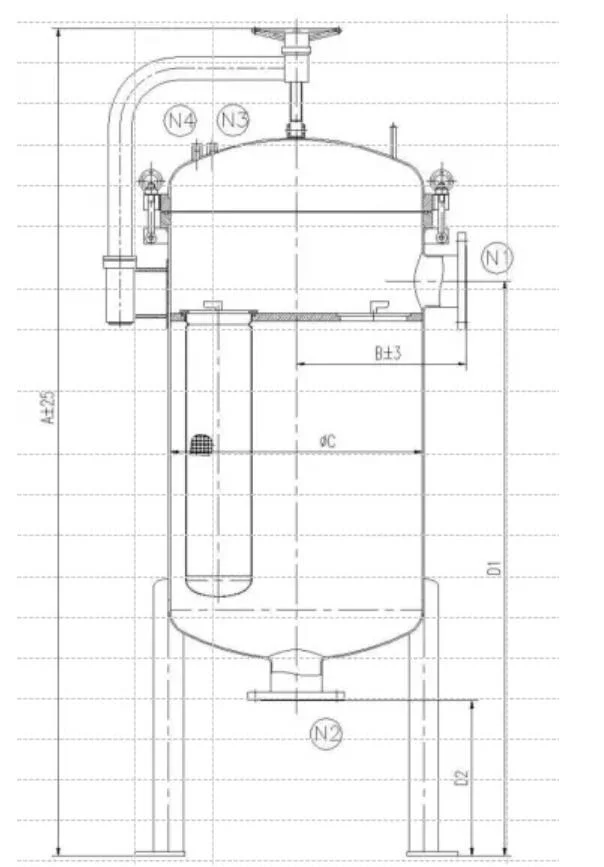

TGDS Multi bags filter is for some coarse filtration and pre-filteration process

JTGDS Standard No. 01 bag or 02 bag, the standard model for 2 ~ 12 bags, and the maximum production customized to 24 bags can basically meet the requirements of various types of flow

FEATURE

• Large flow, Long service life.

• Compact design can reduce occupied space and the loss of liquid

• Side entry and bottom out ensure that liquid medium can be completely discharged, the tangential position outlet, discharging pollution thoroughly, is convenient to be operating.

• The unique three-point clamp device ensures good sealing and avoid liquid side leakage

• The filter housing can add swing arm and the eyebolt or quick-open design, operating conveniently and economically.

APPLICATION

• Food and beverage; bio engineering and pharmaceutical; petrochemical and chemical; automobile manufacturing; petroleum and natural gas; electronic and natural gas; coating, paint, printing ink; nuclear power and thermal power and waste water filtration; liquid and gas purification of liquid and gas.

Surface finish | Operating Conditions | |||||||||||

Finishing Type | Mechanical polishing, electrolytic polishing | Max Operating pressure | 0.6MPa | |||||||||

polishing precision | Inner surface Ra≤0.3μm , Outside surface Ra≤0.4μm. basket 0.6um | Max OperatingTemp. | 150ºC | |||||||||

Material | Connection | |||||||||||

Shell | 304, 316L, SAF2507, | Shell connection | Flange | |||||||||

Vent | 304, 316L | In-outlet N1, N2 | Flange, Tri-clamp, Thread | |||||||||

Eyebolt | 304 | Pressure gauge (option) | 1/2"Female thread | |||||||||

Stabilizer blade | 304 | Drain valve(option) | 1/2" Male thread | |||||||||

O-ring | EPDM, PTFE, Viton, Silicone | |||||||||||

Dimension Parameters | 2pcs | 3pcs | 4pcs | 5pcs | 7pcs |

2# Bag | |||||

A: Total height | 1180 | 1915 | 2030 | 2043 | 2132 |

B: The distance from inlet to center | 300 | 325 | 359 | 378 | 439 |

C: Diameter | Φ400 | Φ450 | Φ500 | Φ550 | Φ650 |

D1:The height from inlet to ground | 1330 | 1350 | 1423 | 1439 | 1480 |

D2:The height from outlet to ground | 300 | 350 | 400 | ||

In-outlet N1, N2 dimension | 4" | 5" | |||

Max flow, m3/h | 80 | 120 | 160 | 200 | 280 |

The above-mentioned data is standard, it can be customized according to customer's requirements. | |||||

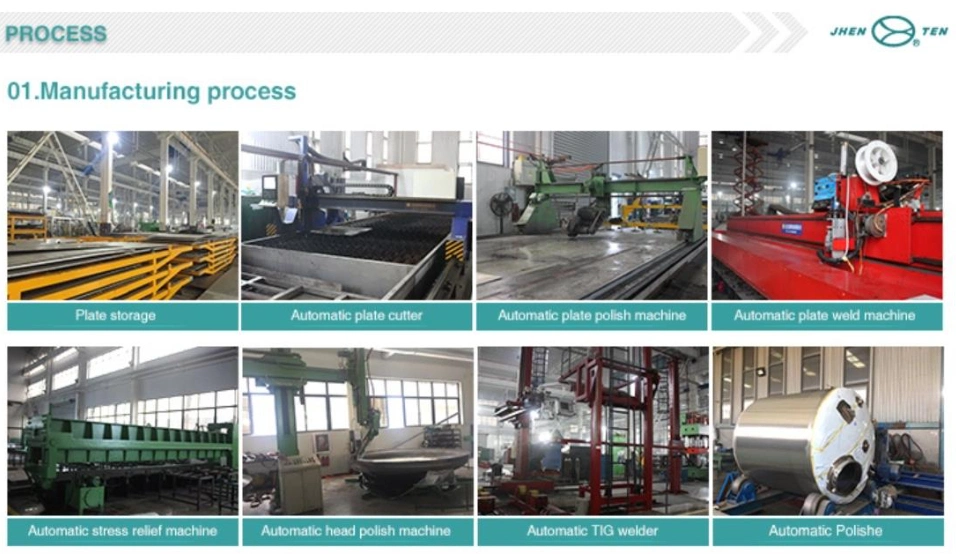

Company Profile

Certifications

Prev: 6000L/H Mineral Water Treatment Machine UF System Ultrafiltration Water Treatment Equipment

Next: UF Membrane Ultrafiltration Tubular Module Hollow Fiber Water Filter Filtration Price

Our Contact